McAllister Technical Services (MTS) was founded in Berkeley, California in 1981. At that time, most scientific equipment was over-priced and not really flexible enough to meet science's ever changing needs. From the very first day, our objective has been to offer the scientific community an alternative to that inflexibility. Our goal has been to offer top quality, genuinely innovative scientific equipment, custom devices and gizmos at a fair price. The scientific community agreed for we have expanded. As we grew, the goal has always been Service(s), just like the name.

Yes, it really is that tall!

Over the course of the years, we have designed and built innumerable devices for the scientific community. The founder, Robert McAllister, has been actively involved in design and manufacturing since 1963, first as an employee for various companies including Lawrence Berkeley Laboratory and, since 1981, has performed and directed design and manufacturing for MTS. A representative sample of products designed and fabricated at MTS can be seen at on this web site and in laboratories all over the world. Of course, all vacuum-exposed surfaces and materials on the devices shown here are fully UHV-compatible.

For design, we use SolidWorks, the leading 3D solid modeling environment that fully integrates parts, assemblies, drawings and bills of material. While there are advantages to the designer using SolidWorks, the real benefit is to the recipient of the design. Using the free viewer, even very complex assemblies can be easily shared and queried (disassembled and measured) without the need to either learn the program or even own a copy of the program.

We have designed and build many long travel translators. One has a vertical travel of 112" (2.8 meters) with XY travel and rotation. See photo at right. All axes were motorized and encoded. It was used to transfer between two floors in the lab, from the analysis chamber upstairs to a LHe dilution refrigerator in the lab one floor below. (The probe took the shortcut but the scientists had to take the stairs.)

Among the more unusual projects we have designed and built is a 3-axis positioner for multiple plasma torches. It is a fully motorized 2 axis gimbal with 12” clear ID and a Z-axis stage is included. All axes were fully motorized and encoded and the Z-axis had a 30” vertical stroke with a lifting capacity of 600 pounds at 15 inches per minute.

Another interesting project was the design and fabrication of a Scanning Tunneling Microscope (STM) to be incorporated into an existing MBE growth and surface analysis chamber at a national laboratory. The challenge was increased by the necessity of maintaining a uniform spacing between the probe tip and sample of a few Angstroms, even while the rest of the system was operating. The researcher routinely is able to resolve individual atoms on 3" Si and GaAs wafers.

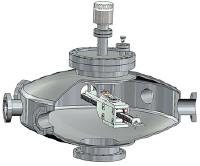

This gizmo was mounted atop a chamber with 8 different ports arranged in a circle, 45° apart. It was designed to extend, receive, retract, rotate and then re-extend a sample, acting as a sort of “railroad roundhouse”. Both the extend / retract and the rotate motions are actuated from a single rotary motion feedthrough, conserving space and reducing cost. For comparison, our price was exactly half of our competitor’s. price.

MTS also builds smaller devices for moving, rotating, heating and cooling in vacuum. Shown here is a specimen holder which includes LN2 cooling, heating and the ability to move the heater closer to the in situ sample.

Please consider McAllister Technical Services for your next design job. We are confident you will find it both rewarding and easy to work with us. We enjoy our work and we enjoy the challenge of a new gizmo, widget or whatever it may be.