One of the major hurdles in the use of many organo-metallic molecules in CVD processes is the lack of thermal stability during volatilization.

This instability can lead to premature decomposition and to contaminant incorporation in the grown film or to the growth of multi component materials. This can result in stoichiometric composition different from that desired; this often leads to undesirable properties of the as-grown materials.

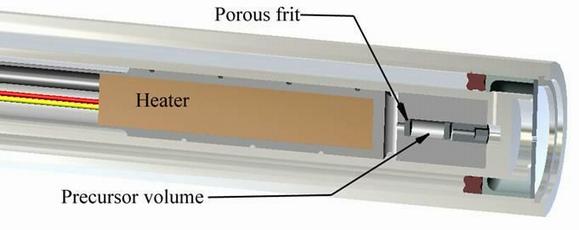

The doser is an UHV-compatible device designed to maximize the volatilization of low vapor pressure precursors for use in chemical vapor deposition processes (CVD) while minimizing dissociation and premature decomposition.

The differentially-pumped doser assembly holds the precursor close to the substrate surface and provides a uniform thermal environment. The material can be removed and changed without breaking vacuum. The design allows the volatilization of low vapor-pressure solid precursors by flowing a preheated carrier gas through the precursor.

- Precursor can be reloaded or changed in minutes, without breaking vacuum

- Robust and easy to use

- A handy knob allows quick isolation or exposure of the precursor to UHV

- Heater has integral thermocouple for accurate temperature control

- Exit apertures can be easily changed for different jobs

Various sizes, styles and accessories are available, as well as a programmable temperature controller for the heater. Contact the factory for details and pricing. See the manual here.