Specifications

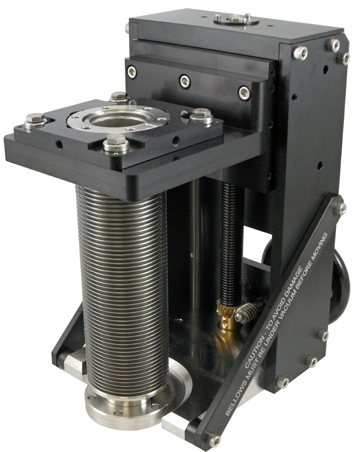

The ZA12-series (and its larger cousins, the ZA45 and ZA60-series) can be used either as a stand-alone Z Axis translator or in combination with an XY stage such as the MC1500 or the MC2000 to produce a long travel XYZ manipulator that is both rigid and cost effective. See the drawing. Despite its modest price, the ZA12-series translator will provide years of trouble-free service, especially if simple maintenance is performed.

The ZA12-series of translators features precision guide rods that are fully supported the entire length of travel. It also includes "Top Flange Tilt". Neither feature is found on other brands. Frequently a probe or other device mounted on a chamber flange will not precisely reach a specified point inside the chamber. This can be due to the mass on the end bending the device and/or inaccuracies of chamber port alignments. The Top Flange Tilt feature allows up to ±2° of tilt adjustment at the top (traveling) flange. This provides even greater stability and rigidity, especially on long travel models. ZA-series translators with strokes of up to 112" (2.8 m) are in use, and are mounted both horizontally and vertically.

The lower (or "fixed") flange can be fitted with in-vacuum support guides for long sample probes. This significantly reduces sag and vibrations in things like long, slim LN2 dewars, sample holders and intro rods. The support bearings are vented and allow clearance for thermocouple and power wires.

All vacuum-exposed materials are stainless steel rated for ultra-high vacuum. The frame mechanism is aircraft-grade aluminum with ball bearings and stainless fasteners.

As delivered, the lead screws are coated with high temperature lubricant. This coating will degrade over time, due bakeouts and use. After bake out, lightly relubricate the screws with the (provided) high temperature grease. Be especially careful not to use a hydrocarbon grease such as Felpro C100TM unless you periodically clean the oxidized residue from all load-bearing surfaces. Be sure to remove the motor and limit switches before bakeout.

The normal bakeout temperature is 150°C but higher temperatures can be used, if needed. For bakeouts between 150°C and 210°C, increase the frequency and thoroughness of lubrication. See the manual for more information.

Options include both stepper motors and DC motors. Both motor options include limit switches. The DC motor option includes a hand held forward/reverse switch and a variable speed control. The ZA series of translators has been designed to allow motors to be easily added in the field, thereby avoiding time consuming, costly factory returns.